Abstract

As a recycling method of waste residue from the liquid fertilizer manufacturing process using turf grass clippings, porous permeable block was prepared by mixing the waste residue from the liquid fertilizer manufacturing process with loess and clay. For the purpose of it, compressive strength, apparent porosity, absorptivity, water permeability coefficient and observation of inner and outer surface morphology using electron microscope were studied. As a results of it, it can be concluded that optimal mixing ratio of waste residue for forming pores in the block was 30%. Mixing with 70% loess was found to be the best mixing ratio in terms of compressive strength, apparent porosity, absorptivity, and water permeability coefficient. In addition, when clay was mixed in the 70% loess to improve durability, the mixing ratio (%) of 50:20 (loess and clay) showed the most stable physical properties, pores, and bonding structure. In addition, the porous permeable block prepared at the optimal mixing ratio exhibited high permeability under a high mechanical strength at 900℃ within the calcination temperature range of 800-1,200℃. The most stable physical properties were obtained during calcination at 900℃ for one hour. The leaching experiment for heavy metals showed that the content of harmful substances in the prepared porous permeable block was below the standard value, demonstrating its safety.

Figures & Tables

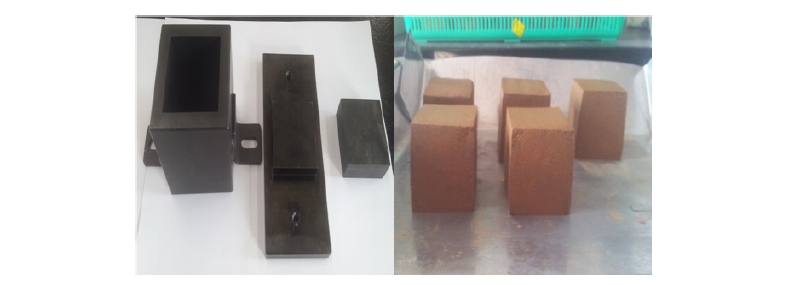

Fig. 1.Making water permeable block. A, Metal mold; B, Water permeable block (5 cm×5 cm×5 cm).